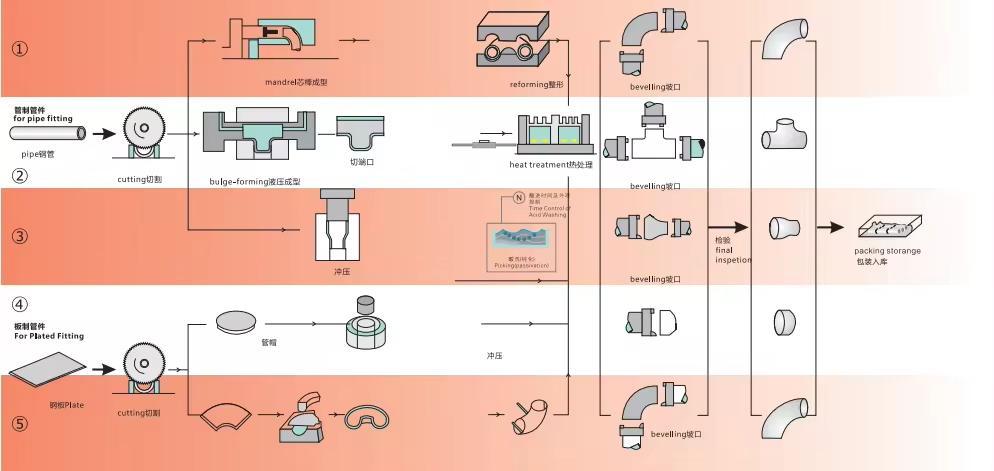

The main function of the tee is to change the direction of the fluid, so that the fluid can be diverted or distributed at the confluence of three identical or different pipelines. According to the pipe diameter, it can be divided into equal-diameter tees and reducing-diameter tees; according to the process, it can be divided into hydraulic bulging and hot pressing forming.

Product Parameters

| Product Name | stainless steel pipe tee |

| Material | stainless steel |

| Process | cold formed |

| Standard | ASTM A403, MSS SP-43;DIN 2605, DIN2609, DIN2615, DIN2616; |

| Grade | SUS304,SUS316, 2520/310S duplex2205/S31803,S32750,S32760,904L,317,347,347H |

| Size | 1/2″-20″ (DN15-DN500) Sch10S-160S |

| Certification | ISO9001, SGS, ROHS |

| End | Beveled Ends |

| Application | Food, beverages, dairy products, beer, and petroleum, fine chemicals |

| Package: | Plywoodwood pallet |

Product Specifications

|

Size |

A Outeiameter |

B CenterHeight |

C Length |

D Thickness |

Weight/Gram |

|

19(3/4″) |

19 |

27.5 |

57 |

1.5 |

40 |

|

25(1″) |

25 |

34.5 |

68 |

1.5 |

67 |

|

32(1 1/4″) |

32 |

37 |

76 |

1.5 |

97 |

|

B8(1 1/2″) |

38 |

48 |

97 |

1.5 |

40 |

|

45(1 3/4″) |

45 |

57.5 |

115 |

1.5 |

213 |

|

51(2″) |

51 |

59.5 |

120 |

1.5 |

249 |

|

57(2 1/4″) |

57 |

64.5 |

130 |

2 |

403 |

|

63(2 1/2″) |

63 |

67 |

136 |

2 |

470 |

|

76(2 3/4″) |

76 |

72 |

145 |

2 |

577 |

|

89(3″) |

89 |

85.5 |

170 |

2 |

786 |

|

102(4″) |

102 |

91 |

185 |

2 |

947 |

|

108(4 1/4″) |

108 |

136 |

190 |

2 |

1070 |

|

133(5 1/4″) |

133 |

118.5 |

240 |

2 |

1047 |

|

159(6 1/4″) |

159 |

140.5 |

279 |

2 |

2250 |

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

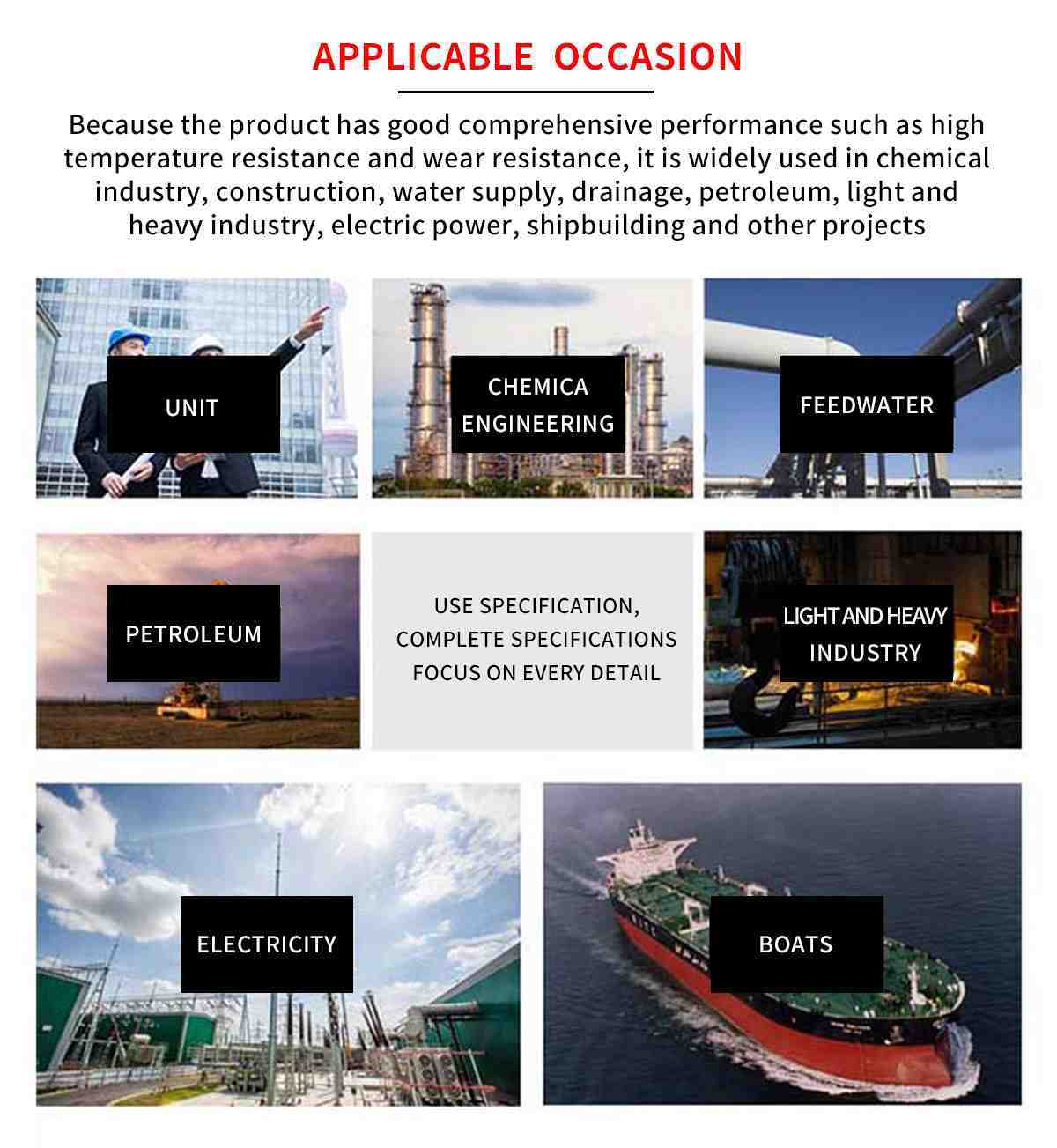

Applications

Additional Processing Technology

Product Packaging

Product Transportation