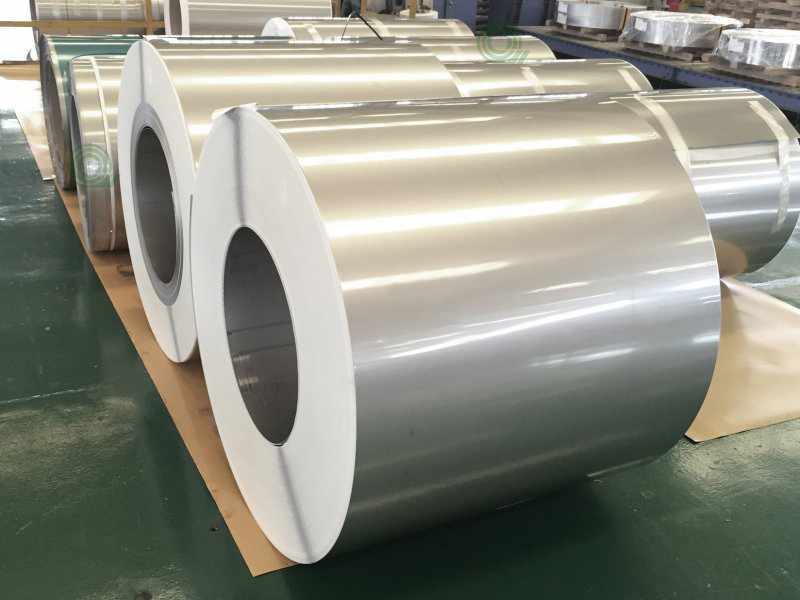

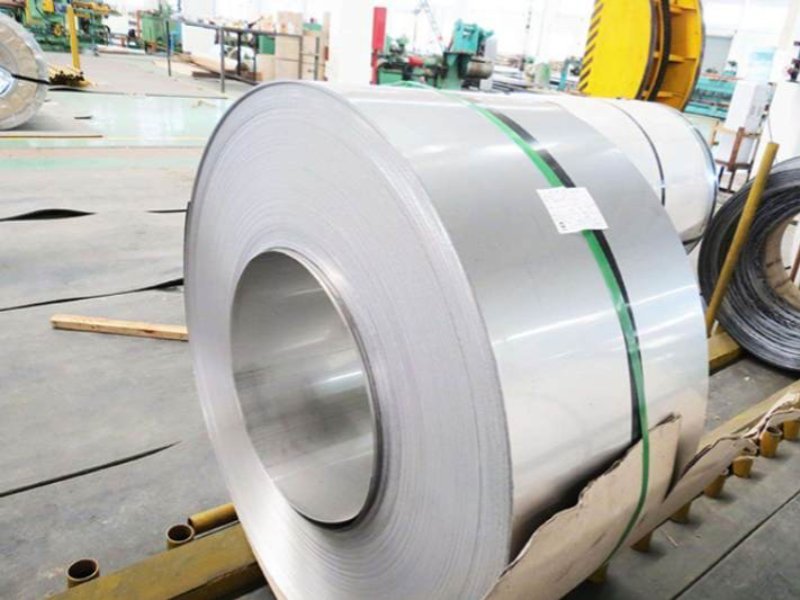

Stainless steel coils are widely used in the construction industry, such as roofs, walls, doors and windows, etc. Because stainless steel coils have good corrosion resistance and oxidation resistance, they can effectively extend the service life of buildings and improve the overall aesthetics of buildings. The application of stainless steel coils in the furniture industry is mainly reflected in the handles, handrails and other parts of furniture. The beauty and wear resistance of stainless steel coils make it an ideal material for furniture manufacturing.

Product Parameters

| Description | |

| Type: | stainless steel coil |

| Thickness | 0.3-200mm |

| Length: | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm,12000mm or as customers’ request |

| Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Standard: | ASTM, AISI, JIS, GB, DIN, EN |

| Surface: | BA, 2B, NO.1, NO.4, HL, 8K, 2D, 2K, 6K, 4K, Mirror |

| Surface Finish: | Polishing, Pickling, Bright, Hairline, Mirror |

| Application: | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, |

| agriculture,and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor | |

| belts, vehicles, bolts, nuts,springs, and screen mesh etc. | |

| Certification: | ISO, SGS,BV |

| Technique: | Cold Rolled/Hot Rolled |

| Welding Line Type: | Seamless,welded |

| Edge: | Mill Edge/Slit Edge |

| Quality: | SGS Inspection |

| American Standard | ASTM A959:304/305/3095/3105/316/317/321/347/630/904L/2205/2304/2507 |

| UNS:S30400/S30500/S30908/S31008/S31600/S31603/S31651/S31609/S31653/S31700/S31703/S32100/S34709/S17400/N08904/S31803/S32205/S32304/S32750/S32760 | |

| European standard | EN 10088-2/EN 10095/X5CrNi18-10/X2CrNi19-11/X12CrNi23-13 |

| X8CrNi25-21/X5CrNiMo17-12-2/X2CrNiMo18-14-3/X2CrNiMoN17-13-3/X2CrNiMo18-15-4/X6CrNIT18-10/X10CrNIT18-10/X6NINb18-10 | |

| German standard | DIN17006:X5CrNi18-10/X2CrNi19-11/X2CrNiN18-10/X7CrNi23-14/X12CrNi25-21/X5CrNiMo17-12-2/X2CrNiMo18-14-3/X2CrNiMON17-13-3/X5CrNIMo17-13/X2CrNiMo18-16-4/X6CrNIT18-10/X12CrNIT18-9 |

| etc. | |

| 1.4301/1.4306/1.4948/1.4845/1.4401/1.4404/1.4919/1.4429/1.4449/1.4438/1.4541/1.4550/1.4539/1.4462/1.4362/1.4410/1.4501. | |

| Japanese standard | JIS G4303 JIS G4311: SUS304/SUS304L/SUS304HTB/SUS304HFB/SUS304N1/SUS305 |

| SU53095/SUS310S/SUS316/SUS316L/SUS316N/SUS316H/SUS316LN/SUS317/SUS317L/SUS321/SUS321HTB/SUS347/SUS347HTB/5US630/SUS317J5L/SUS329J3L. | |

| Main market: | Asia/Europe/ South America |

| Supply Ability: | 5000 Ton/Tons per Month |

| Packaging & Delivery: | In bundle,plastic bags,thin film,wooden pallet,standard seaworthy export packing or as customer demands |

Product Specifications

| Type | Thickness(mm) | Width(mm) | Type | Thickness(mm) | Width(mm) | ||||||

| 1219 | 1500 | 1800 | 2000 | 1219 | 1500 | 1800 | 2000 | ||||

| Cold Rolled | 0.3 | √ | √ | √ | √ | Hot Rolled | 4.0 | √ | √ | √ | √ |

| 0.4 | √ | √ | √ | √ | 5.0 | √ | √ | √ | √ | ||

| 0.5 | √ | √ | √ | √ | 6.0 | √ | √ | √ | √ | ||

| 0.6 | √ | √ | √ | √ | 8.0 | √ | √ | √ | √ | ||

| 0.7 | √ | √ | √ | √ | 10.0 | √ | √ | √ | √ | ||

| 0.8 | √ | √ | √ | √ | 12.0 | √ | √ | √ | √ | ||

| 0.9 | √ | √ | √ | √ | 14.0 | √ | √ | √ | √ | ||

| 1.0 | √ | √ | √ | √ | 16.0 | √ | √ | √ | √ | ||

| 1.2 | √ | √ | √ | √ | |||||||

| 1.5 | √ | √ | √ | √ | |||||||

| 1.8 | √ | √ | √ | √ | |||||||

| 2.0 | √ | √ | √ | √ | |||||||

| 2.5 | √ | √ | √ | √ | |||||||

| 3.0 | √ | √ | √ | √ | |||||||

| 4.0 | √ | √ | √ | √ | |||||||

| 5.0 | √ | √ | √ | √ | |||||||

| 6.0 | √ | √ | √ | √ | |||||||

| Or according to the size requested by the customer | |||||||||||

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

Stainless Steel Coil is widely used in fields such as tableware, household appliances, machinery manufacturing, building decoration, coal, petrochemical, etc. due to its excellent corrosion resistance, heat resistance, and low temperature resistance.

Project Cases

Additional Processing Technology

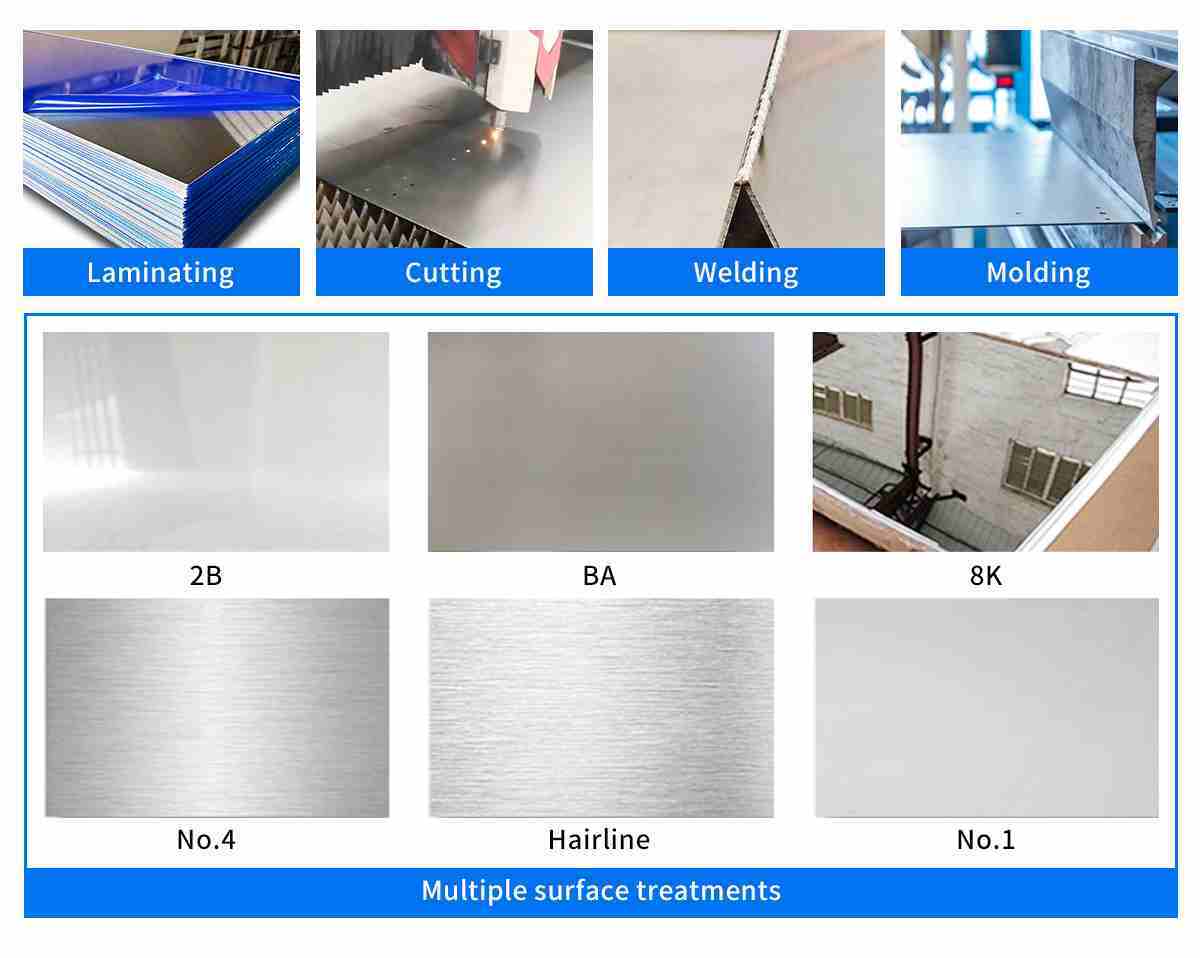

Our stainless steel coils can provide processing techniques such as lamination, cutting, welding, pressing, and surface treatment.

Product Packaging

Product Transportation