Flanges are widely used in pipeline systems in industries such as petroleum, chemical industry, natural gas, electricity, metallurgy, and construction. Flanges are mainly used for pipeline connection, and can be detachably connected by bolt fastening, which is convenient for installation and maintenance.

Product Parameters

| Product name | Stainless steel pipe flange |

| Standard | ANSI, bs, DIN, GB, ISO, JIS, Jpi, ASME |

| Material | SS304L, SS316L, SS304, SS201 ect. |

| Certification: | ISO9001,ISO14001,ISO45001 |

| Connection type | Raised Face, Flat Face, Ring Type Joint, Lap-Joint Face, Large Male-Female, Small Male-Female,Large tongue groove, Small tongue groove etc |

| Woking pressure: | ≤1.6 Mpa |

| Temperature Range: | -10degree to +150degree |

| Tolerance: | ± 1% |

| Design: | OEM & ODM |

| Thickness | SCH5-SCH160 |

| Size | 1/2′ ~ 48′ |

| Type | Butt Welded |

| Surface Treatment: | Pickled surface/Ground polished surface |

| Application | It is usually used in constructions,petroleum, chemical industry, power, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc. |

| Package |

Standard export wooden case or as you requested |

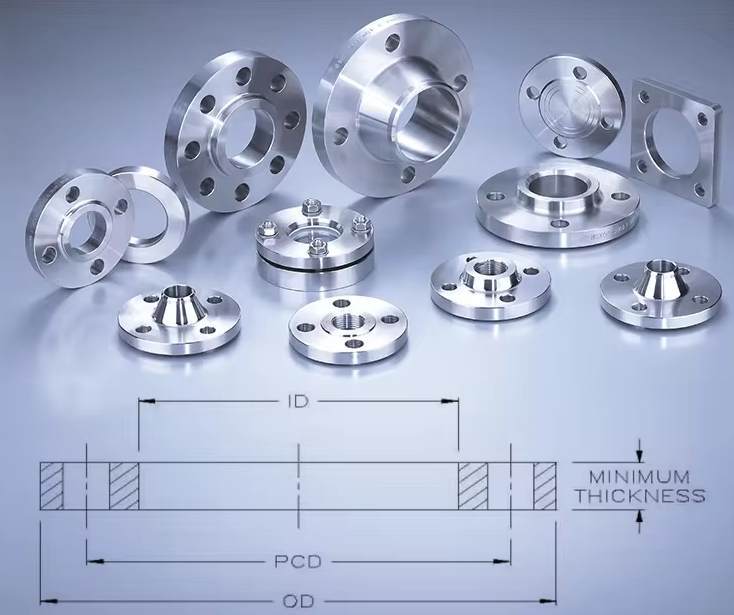

Product Specifications

|

Steel Flanges EN1092/ISO7005 |

||||||||

|

Pipe Size |

DN |

PN |

OD |

PCD |

ID |

Bolt No. |

Bolt Hole Dia |

Thickness |

|

50 |

40 |

16 |

150 |

110 |

55 |

4 |

18 |

18 |

|

63 |

50 |

16 |

165 |

125 |

68 |

4 |

18 |

20 |

|

75 |

65 |

16 |

185 |

145 |

80 |

4 |

18 |

20 |

|

90 |

80 |

16 |

200 |

160 |

95 |

8 |

18 |

20 |

|

110 |

100 |

16 |

220 |

180 |

116 |

8 |

18 |

22 |

|

125 |

125 |

16 |

250 |

210 |

130 |

8 |

18 |

22 |

|

140 |

125 |

16 |

250 |

210 |

150 |

8 |

18 |

22 |

|

160 |

150 |

16 |

285 |

240 |

170 |

8 |

22 |

24 |

|

180 |

150 |

16 |

285 |

240 |

188 |

8 |

22 |

24 |

|

200 |

200 |

16 |

340 |

295 |

210 |

12 |

22 |

26 |

|

225 |

200 |

16 |

340 |

295 |

235 |

12 |

22 |

26 |

|

250 |

250 |

16 |

405 |

355 |

265 |

12 |

26 |

29 |

|

280 |

250 |

16 |

405 |

355 |

290 |

12 |

26 |

29 |

|

315 |

300 |

16 |

460 |

410 |

335 |

12 |

26 |

32 |

|

355 |

350 |

16 |

520 |

470 |

365 |

16 |

26 |

35 |

|

400 |

400 |

16 |

580 |

525 |

420 |

16 |

30 |

38 |

|

450 |

450 |

16 |

640 |

585 |

470 |

20 |

30 |

42 |

|

500 |

500 |

16 |

715 |

650 |

520 |

20 |

33 |

46 |

|

560 |

600 |

16 |

840 |

770 |

575 |

20 |

36 |

55 |

|

630 |

600 |

16 |

840 |

770 |

650 |

20 |

36 |

55 |

|

710 |

700 |

16 |

910 |

840 |

740 |

24 |

36 |

63 |

|

800 |

800 |

16 |

1025 |

950 |

830 |

24 |

39 |

74 |

| Steel Backing Ring ANSI B16.5 | |||||||

| Pipe Size | DN | OD | PCD | ID | Bolt No. | Bolt Hole Dia | Thickness |

| 50 | 1 1/2″ | 127 | 98.6 | 63 | 4 | 16 | 17.5 |

| 63 | 2″ | 152 | 120.5 | 68 | 4 | 20 | 19.5 |

| 75 | 2 1/2″ | 178 | 139.5 | 80 | 4 | 20 | 22.5 |

| 90 | 3″ | 190 | 152.5 | 95 | 4 | 20 | 24 |

| 110 | 4″ | 229 | 190.5 | 116 | 8 | 20 | 24 |

| 125 | 5″ | 254 | 216 | 130 | 8 | 22 | 24 |

| 140 | 5″ | 254 | 216 | 150 | 8 | 22 | 24 |

| 160 | 6″ | 279 | 241.5 | 170 | 8 | 22 | 25.5 |

| 180 | 6″ | 279 | 241.5 | 188 | 8 | 22 | 25.5 |

| 200 | 8″ | 343 | 298.5 | 210 | 8 | 22 | 29 |

| 225 | 8″ | 343 | 298.5 | 235 | 8 | 22 | 29 |

| 250 | 10″ | 406 | 362 | 265 | 12 | 26 | 30.5 |

| 280 | 10″ | 406 | 362 | 290 | 12 | 26 | 30.5 |

| 315 | 12″ | 483 | 432 | 335 | 12 | 30 | 32 |

| 355 | 14″ | 533 | 476 | 365 | 12 | 26 | 35 |

| 400 | 16″ | 597 | 540 | 420 | 16 | 30 | 37 |

| 450 | 18″ | 635 | 578 | 470 | 16 | 33 | 40 |

| 500 | 20″ | 698 | 635 | 520 | 20 | 33 | 43 |

| 560 | 24″ | 813 | 749.5 | 575 | 20 | 36 | 48 |

| 630 | 24″ | 813 | 749.5 | 650 | 20 | 36 | 48 |

| 710 | 28″ | 927.1 | 863.6 | 740 | 28 | 35 | 52.4 |

| 800 | 32″ | 1060.4 | 977.9 | 830 | 28 | 41 | 57.1 |

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

Product Packaging

Product Transportation